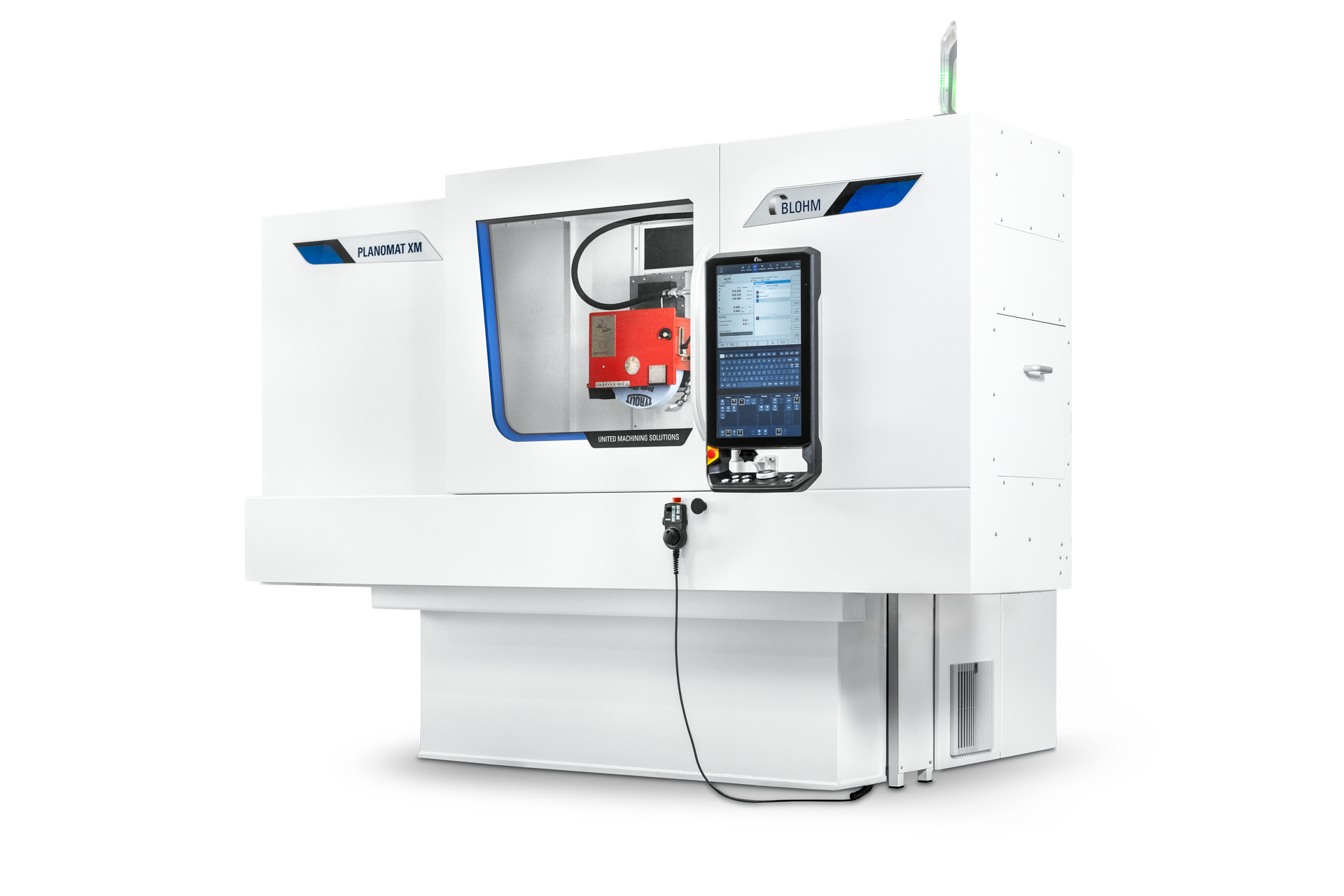

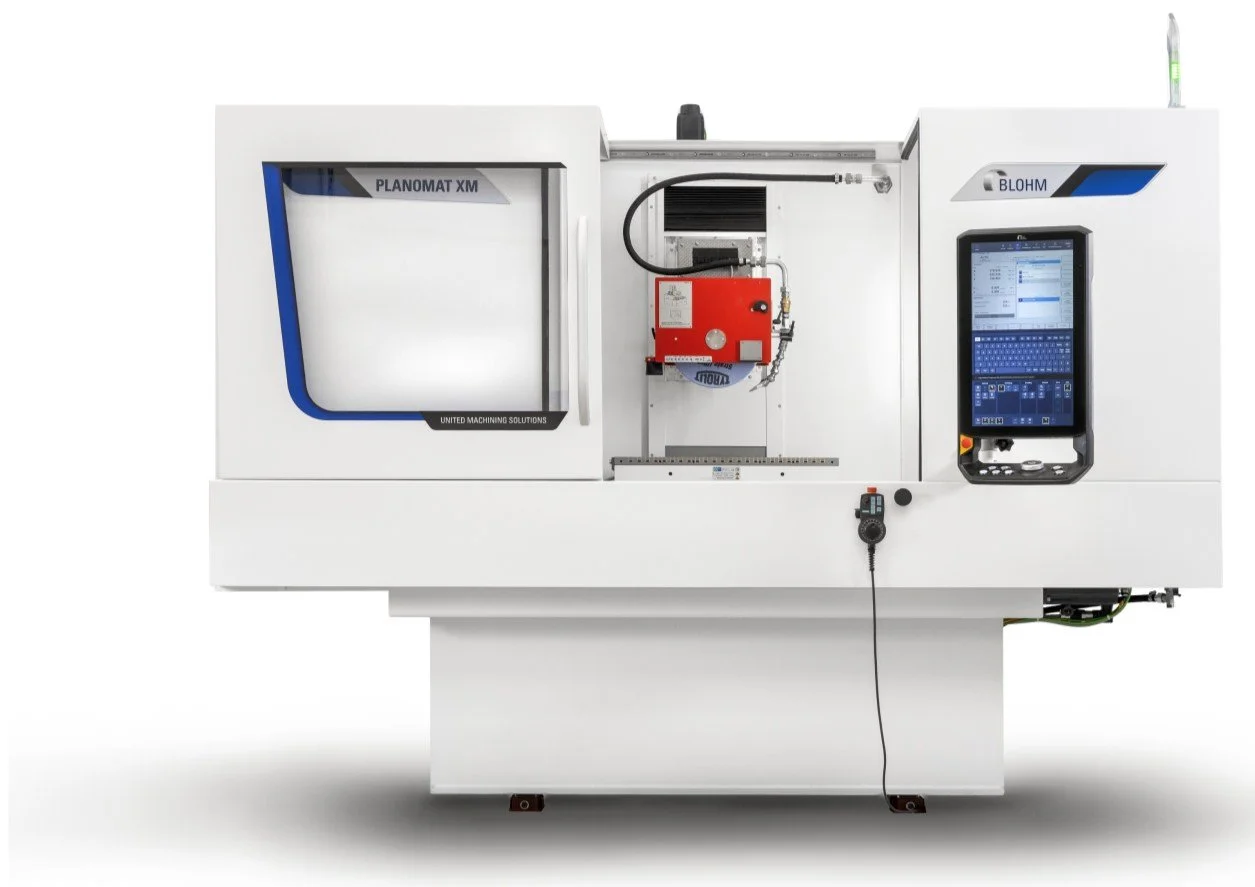

PLANOMAT XM

PLANOMAT XM

UNIVERSALLY DESIGNED, READY FOR THE FUTURE

Repeatability and precision have been your and our goal for over 100 years

Versatility with flexible software and intuitive operation

High availability with worldwide service support – remote and on-site

REPEATABILITY

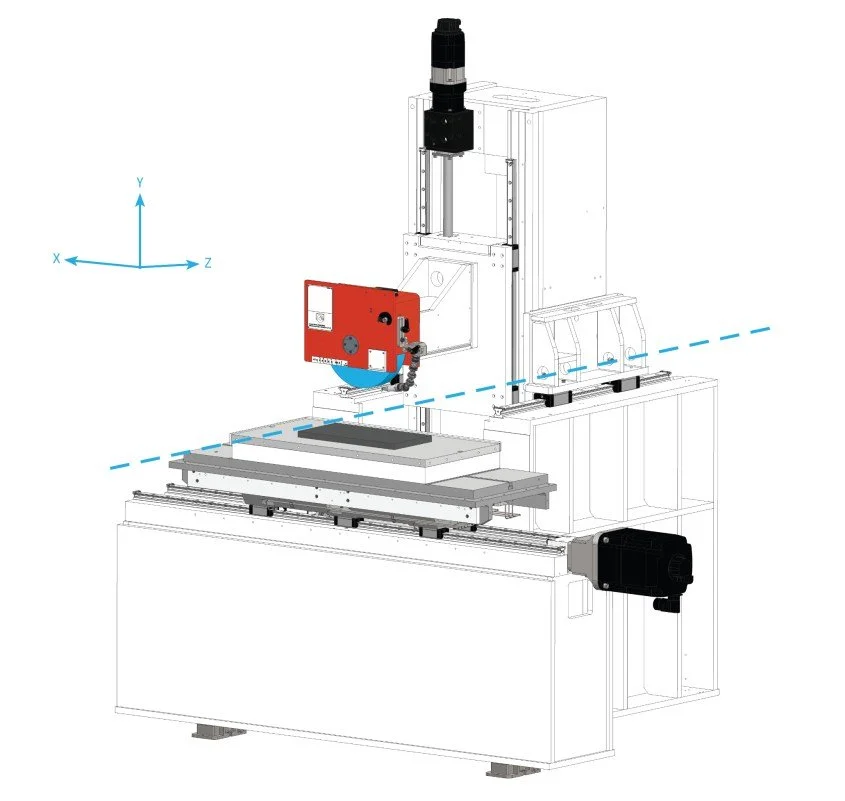

The unique 3-leg design ensures stability and geometric accuracy throughout its service life. Highest repeatability thanks to the heavily ribbed construction with a machine weight of 5 tons.Highest repeatability of workpiece accuracy even with fluctuating ambient temperatures

Highest repeatability over the lifetime of the machine

PRECISION

PLANOMAT's unique raised of the Z-guides drastically minimizes the bending force on the column for maximum rigidityHigher flatness across the entire workpiece

Reduction of edge chipping on the workpiece

Visual improvement of the workpiece through consistent grinding pattern

VERSATILITY

Working area 400 x 800 mm

Spindle distance to table 600 mm

Travel strokeX-axis 900 mm

Y-axis 500 mm

Z-axis 360 mm

Siemens Sinumerik One control

BLOHM operator guidance with grinding technologiesPendulum grinding

Creed feed grinding

Faces grinding

Profile grinding

PERFORMANCE DATA

Linear guide ways in all axesLength measuring system in Y-/Z-axis

Accuracy resolution 0.001 mm

Ground ball screws in all axesX-axis speed 30,000 mm/min

Y/Z axis speed 3,750 mm/min

Grinding spindleGrinding spindle drive 8 kW

Grinding wheel peripheral speed 63 m/s

Grinding wheel dimensions 300 x 50 x 76.2 mm

Table load max. 800 kg

MACHINE LAYOUT

Compact machine designElectrical cabinet integrated in the machine

Large sliding door for excellent accessibility to the working area

Maintenance-friendly machine designComplete housing in welded design to prevent leaks

Maintenance doors on the right and left side of the work area paneling

No open cable routing

No cable routing through the machine bed

Control Hardware:

C.O.R.E. Panel

Fully modular system

Design characteristics: very high rigidity, minimum vibrations, minimized thermal influences

Precison linear guideways

High quality, recirculating ballscrews

Option: linear direct drive (X-axis)

Software:

C.O.R.E. OS operating system

Optimal operator guidance

Programming with menu-guided grinding and dressing cycles

UNITED GRINDING Digital Solutions™

INTUITIVE OPERATION

Graphical user interface

Quick programme creation using drag and drop

Quick adjustment of grinding and dressing cycles using parameters

Standard grinding cycles for all flexible grinding tasks, extended grinding cycles Interpolation and profile grinding with Grips Profile

Comprehensive tool management with 50 grinding wheels and 15 dressing tools

ADVANCED GRINDING CYCLES INTERPOLATION (OPTIONAL)

Deep grinding at angles in the X/Y plane with a single cut

Deep grinding of convex or concave radii

Path-controlled deep grinding X/Y and path-controlled pendulum grinding in Y/Z (option Grips Profile required for this)

PROFILE GRINDING WITH GRIPS PROFILE (OPTIONAL)

GripsProfile software is installed on the machine control system. Additional use on an external PC is also possible with the software dongle.

17 predefined standard contours

Import of DXF contours

CAD module for free geometries

PROFILE GRINDING WITH GRIPS PROFILE (OPTIONAL)

Selection of various dressers and pre-dressers

Dressing logic for contour, position and axis-parallel dressing

Generation of path grinding programmes in the X/Y or Y/Z direction

Automatic generation of the dressing programme

Simulation of contour creation with automatic collision checking

AUTOMATIC MEASURING PROBE

Mounted on the left side of the disc guard with a pneumatic stroke of 300 mm

Cycles for workpiece detection and pre-positioning in the X, Y and Z axesAutomated processes in the area of multiple clamping

Reliable detection of workpiece position

Automatic grinding of workpieces to final height

A wide variety of measuring tasks possible