Your Custom Text Here

Schläfli Engineering AG was founded on March 28, 1990 in Büren a/A (Switzerland). The company designs and produces bore sizing, shape grinding, polishing and wire guided centerless grinding machines with processes that maximize all key quality aspects of small parts: diameter, roundness, cylindricity, concentricity and surface finish.

The machines are best suitable, among many other operations, for the watch, textile, automotive, tool and medical industry. They are perfectly adaptable for the machining of dies, nozzles, bushings, bearings, watch & industrial ruby and sapphire, gear wheels and ferrules. They can machine ultra hard material to relatively soft materials.The machines are suitable to hone bores from 0.05mm-2mm.

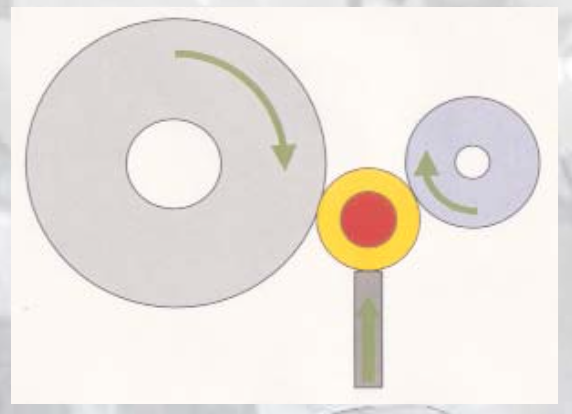

The wire-DSM (Diamond Suspension Machining) Process

Our business is creating the perfect small bores. The key factor in our wire-DSM process is a high precision wire that acts as a carrier of a diamond paste suspension. The coil-fed wire, coated with diamond paste, passes through the bores to be machined. During the process, the parts to be machined rotate and the wire oscillates in an axial direction in relation to the wire’s center line. The wire itself has a slightly tapered section. It is this taper which gradually increases the bores’ diameter before the following cylindrical section provides, in the final stages of operation, the correct bore sizing and accuracy. It is important to realize that the wires can be reused many times and exchanged, including set up, within 2 minutes.

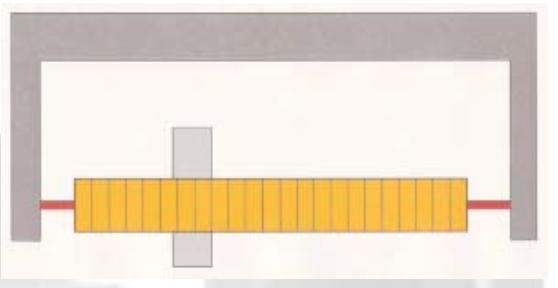

The Centerless Grinding Process

The PreciGrind 2000 is a centerless grinding machine designed to achieve, besides tight diameter tolerances, high concentricity accuracy (ID to OD). The parts to be ground must have an accurate bore through which a high precision wire is pulled. The parts threaded onto this guiding wire form a processing chain of parts up to 35 1/2” / 900 mm in length. The wire is mounted onto the oscillating axis of the machine. The grinding process is based upon a standard centerless grinding machine concept.