S36-The high-performance machine for automated processes.

S36-The high-performance machine for automated processes.

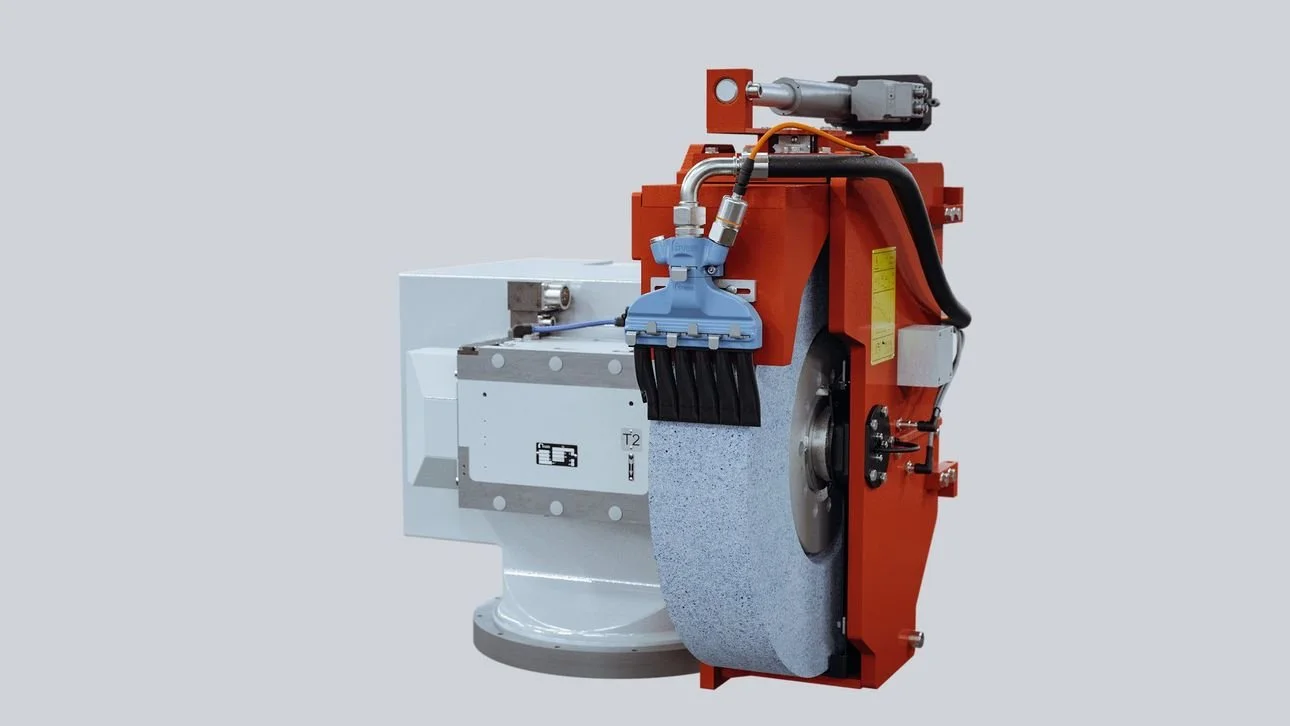

The S36 was in part designed to respond to increasing demand for e-mobility production solutions. The machine has a grinding wheel with a diameter of 610 mm (24") and width of 125 mm (4.92") for grinding current and future workpieces in this sector both economically and efficiently. Grinding wheel power of 15 kW (20 HP) and the large grinding wheel enable efficient and safe machining of automotive and hydraulic components in one clamping process with maximum precision.

Technical Data

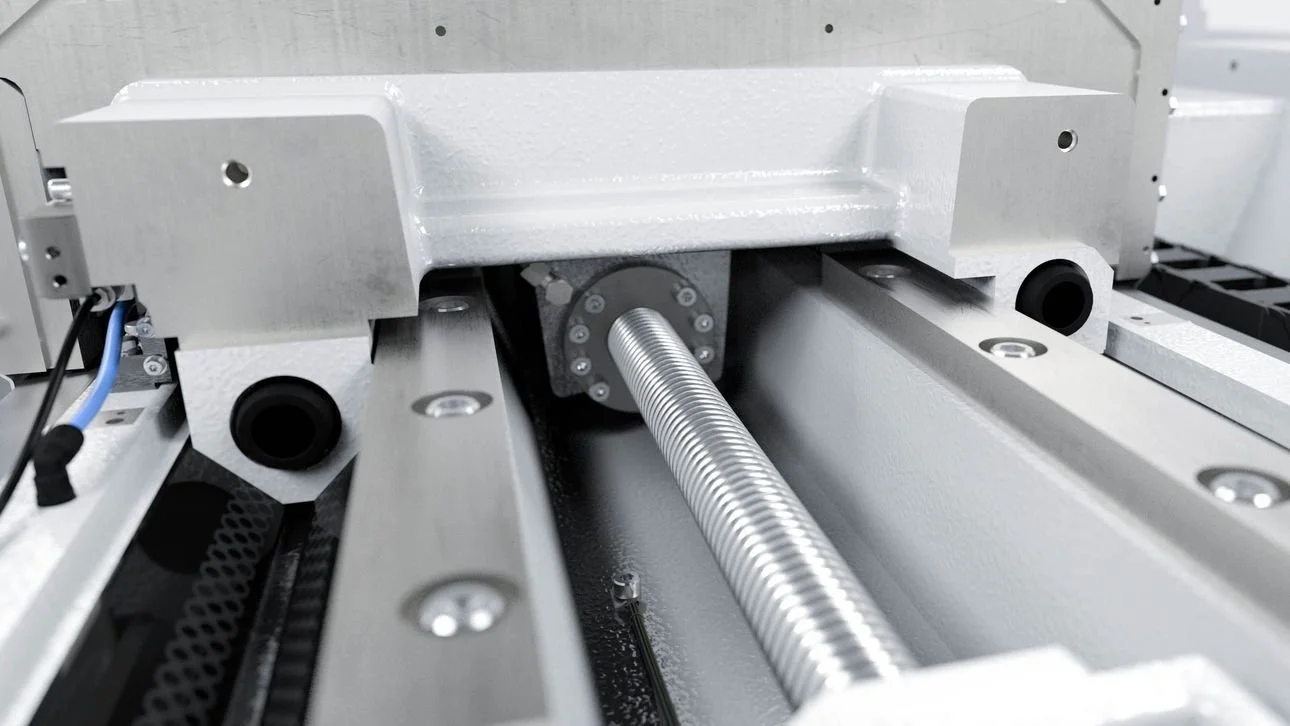

Linear Axes

Max. Travel X 370 mm

Max. Travel Speed X 15'000 mm/min

Max. Travel Z 800 mm

Max. Travel Speed Z 20'000 mm/min

Spindle drive

Max. Spindle Power 15 kW

Max. Number Of Revolutions 1'500 /min

Max. Grinding Wheel Diameter 610 mm

Max. Grinding Wheel Width 125 mm

Swiveling Axes

Swiveling Range C∞ °

Workpiece Data

Workpiece Length 800 mm

Workpiece Diameter 449 mm

Max. Workpiece Weight 150 kg

Distance Between Centers 650 mm

Center Height 225 mm

Hardware:

External wheelhead with grinding wheel right, 0° / 15° / 30°

Frequency-controlled motor grinding spindle for external grinding

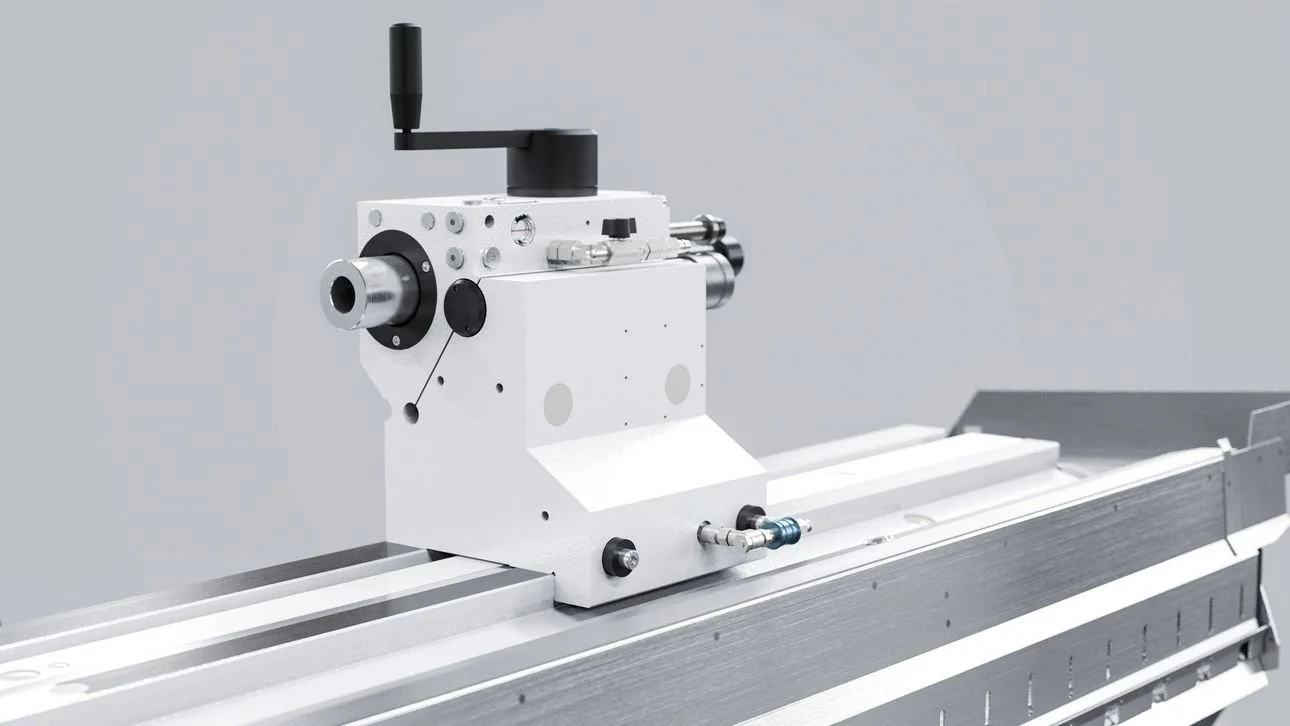

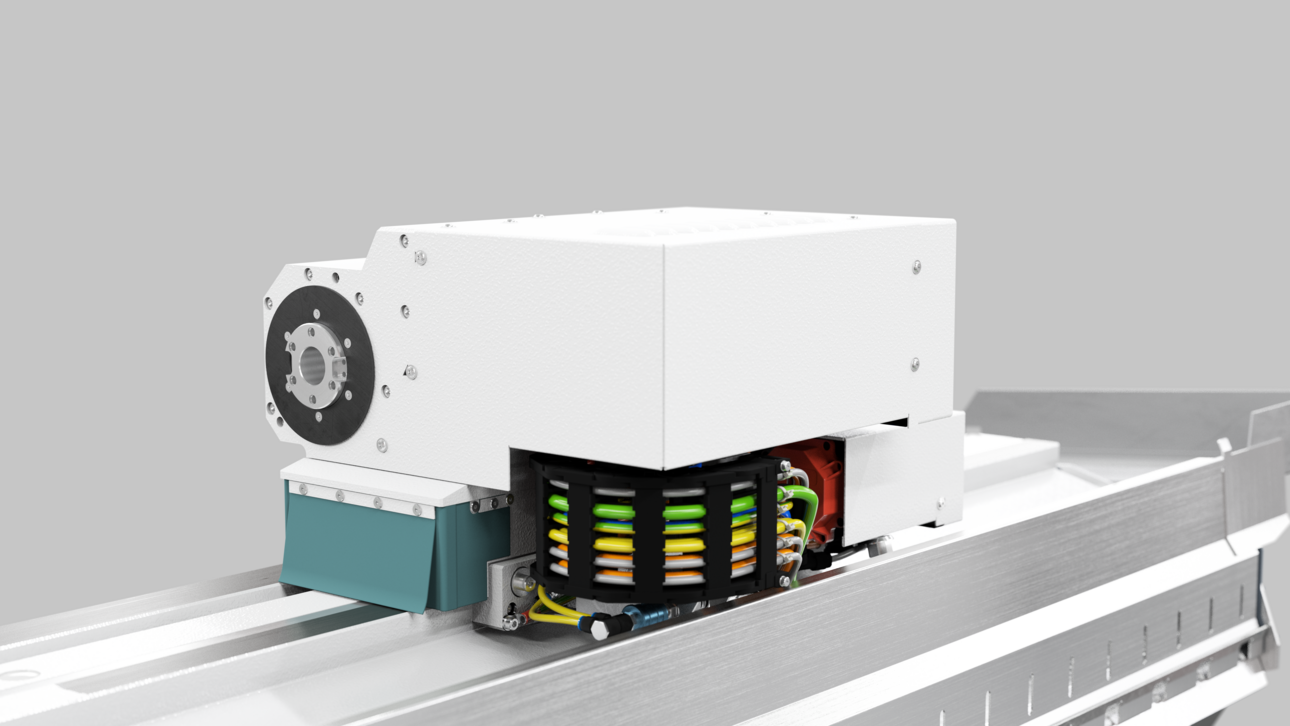

C axis for workhead

Worktable with integrated double T-slot for dressing unit

C.O.R.E. Panel

Full enclosure with two sliding doors

Granitan® S103 mineral-cast machine base

Software:

C.O.R.E. OS operating system

Very simple programming thanks to StuderPictogramming

Standardized interfaces for loader and peripheral units

Flexibly upgradeable with integrated software modules

StuderWIN programming software (optional) for creating grinding and dressing programs on an external PC