Based in Sutton-in-Ashfield, Nottinghamshire, R&D Leverage provides expert technical solutions to the European plastic packaging industry. The busy company serves a wide range of demanding industries including the food and beverage, medical, cosmetics, household and personal care markets.

The work of R&D Leverage UK, together with that of R&D Leverage USA, has enabled the business to develop into one of the foremost providers of quality tooling for the world's packaging industries. R&D Leverage’s UK plant produces one stage, injection stretch blow mould (ISBM) tooling for PET containers.

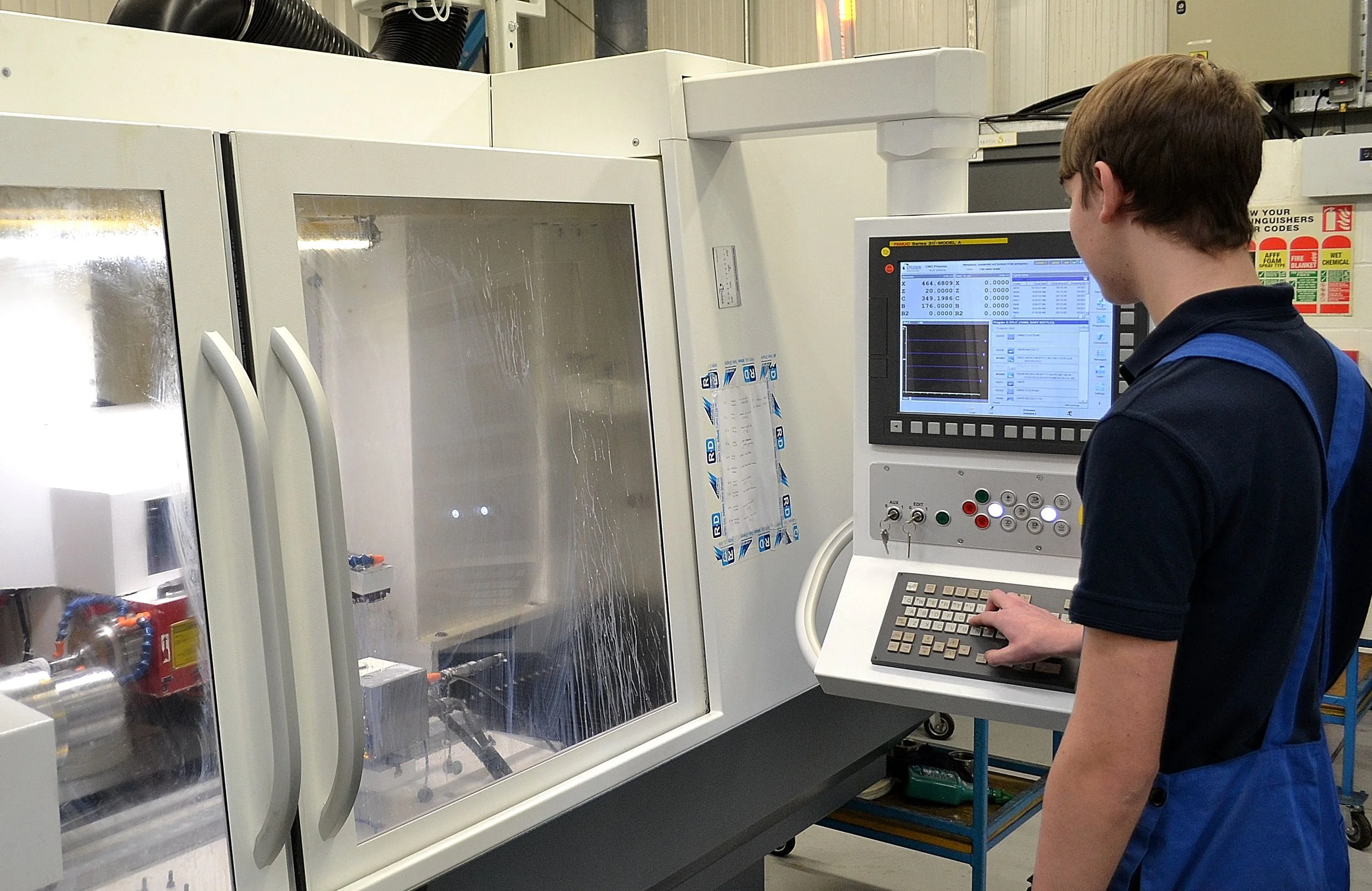

Certified to BS EN ISO 9001:2000, R&D Leverage UK is equipped with a wide range of innovative design, production and inspection aids that help ensure the delivery of on-time, on-budget, premium quality moulds. In addition to the company’s advanced machine tools delivering the required quality and accuracy, R&D Leverage UK believe that purchasing the best available, most productive machines provides the levels of efficiency that enables it to compete in what is a fiercely competitive sector. This philosophy is reflected in the company’s recently installed, second Studer S31 cylindrical grinder purchased from UK Studer agent Micronz.

Having been delighted with the performance of the company’s first Studer S31, ever increasing demand for the company’s moulds recently prompted the purchase of the second machine from the famous Swiss manufacturer.

R&D Leverage UK, Managing Director, Alan Tolley explained. “From our high-tech Sutton-in-Ashfield plant, we are the Complete Solution Provider for a wide range of packaging sectors across Europe and beyond.

“We have established an excellent reputation for the reliability of our products and for our use of the best available technology. When investing in machine tools, our aim is to maintain our high quality standards and also, mindful of our constant quest for further efficiencies, to enable the manufacture of our molds to be achieved faster than before.

“Before purchasing our first Studer S31 grinder we searched for a machine that would satisfy both our quality and our efficiency requirements. Having witnessed demonstrations of several suitable machines, we decided that the Studer S31 ticked all of our boxes. Having specified the machine to match our exact needs, given the excellent reputation of the Studer brand, we were pleasantly surprised that the supplied quote was very close to the cost of other, less capable grinders.

“Following its installation, the ease of use of our first Studer grinder meant that it was soon turning-out the promised volumes of ground components with excellent dimensional and surface finish characteristics. Since this time the grinder has maintained it impressive performance and has proven to be extremely reliable.

“When demand for ground parts recently further increased, our positive experience with our first S31 and the excellent service we have received from Studer UK agent Micronz, meant that we remained loyal to the brand. Once again, we were able to work closely with Mark Maurice, the owner of Micronz to specify a Studer S31 grinder that matched our evolving needs. Now fully operational, our new Studer S31 cylindrical grinder is now producing the expected high volumes of premium quality ground components and it has removed the potential for bottle-necks in our grinding department.”

The compact Studer S31 CNC universal cylindrical grinding machine, as purchased by R and D Leverage, is designed for the grinding of medium-sized workpieces with external and internal grinding in a single clamping. The versatile S31 is able to grind workpieces in customized as well as small and large-batch production runs. The S31 can be adapted precisely to the demands placed on it; this flexibility guarantees an optimal price / performance ratio.

With the ability to machine workpieces with a maximum weight of 80 / 120 kg, Studer’s S31 has distances between centres of 650 / 1000 mm, a centre height of 175 mm and has a grinding wheel diameter of 500 mm.

The machine’s solid Granitan base forms the basis of a cylindrical grinding machine that is equipped with high-quality components, guaranteeing maximum precision, performance and reliability over many years. The material structure developed by Studer, that has proven its efficiency over many years, is produced in the company’s own plant using the most modern industrial techniques. The excellent cushioning behaviour of the S31’s machine base ensures outstanding surface quality of the ground workpieces and an increased service life of grinding wheels, further reducing downtime.

The S31’s full enclosure allows the use of emulsions or oils as cooling lubricants, whilst two large sliding doors provide users with easy access. For highly-efficient automated, 24 hour running, handling devices can be connected via the machine’s defined loader interface.

The S31’s longitudinal and cross slides V and flat guideways have a non-abrasive Granitan S200 slideway coating and are moulded directly into the machine base. The guideways offer the highest possible accuracy throughout the machine’s entire speed range with high load capacity and excellent cushioning levels.

The swivelling wheelhead enables the external, internal and form grinding of workpieces in a single clamping. The wheelhead is equipped with a water-cooled, maintenance-free motor-spindle mounted on roller bearings, with infinitely variable speed control. External grinding wheels with a diameter of 500 mm (20") and a width of 63 (80 F5) mm (2.5" / 3.15") are fitted to the shaft ends. Efficient high-frequency spindles with an external diameter of 120 mm (4.72") are used for internal grinding.

The S31 also features a frequency-controlled motor-driven grinding spindle for external and internal grinding, whilst the machine’s C axis workhead enables efficient and accurate form and thread grinding

The use of Studer’s practical grinding software with its proven pictogramming allows less experienced users to quickly optimise the full potential of the S31. StuderGRIND software is also available, enabling efficient programming of special applications, such as form and thread grinding.

http://www.rdleverage.com